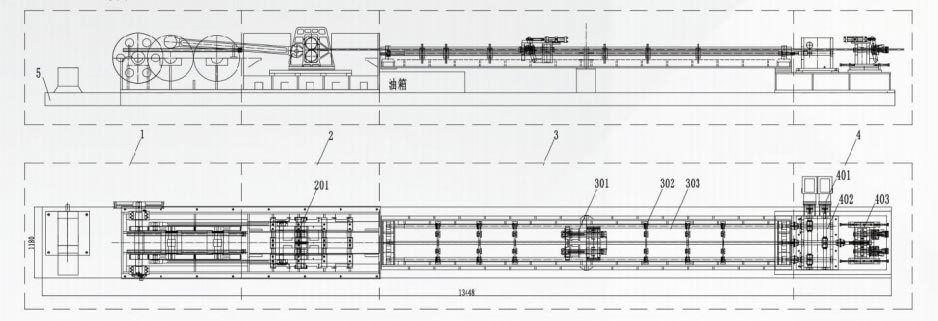

LG15X2-G Cold rolling pipe mill

Classification :

Line:Single/Double Line

OD range: 9-20mm

Suitable for: Round pipes

Keywords:

Cold rollng pipe mill

PRODUCT DETAILS

Product Parameters

The LG15X2-G series is a customized cold roling pipe il tailored to the material characteristics of stainless steel ilets.This roling mill adopts an overall platform assembly method,integrating equipment,motor,hydraulic station,oil tank,and control system.No need to excavate the foundation,overllinstalltion,easy to install nd use,very convenient.At the sametime,this rolling mil as the characteristics of high efficiency and high stability.

|

Number |

name |

unit |

LG15×2-G |

|

1 |

Outerdiameter of tube blank |

mm |

φ16-φ33 |

|

2 |

Tube blank thickness |

mm |

1-3 |

|

3 |

Tube blank length |

m |

2-6 |

|

4 |

Tube blank outer diameter toleranco |

mm |

±0.2 |

|

5 |

Pipeblank wall thicknesstolerance |

mm |

±0,1 |

|

6 |

Bending degree of pipe blank |

mm/m |

≤3 |

|

7 |

Outer diameter of finished pipe |

mm |

φ9-φ22 |

|

8 |

Finished pipe wll thickness |

mm |

0.85-3 |

|

9 |

Finished pipe length |

m |

≤15 |

|

10 |

Outer diameter toleranceof finishedpipe |

mm |

±0.03 |

|

11 |

Finished pipe wall thickness tolerance |

mm |

60% |

|

12 |

Elongation coefficlent |

|

≤3.5 |

|

13 |

Feed volume |

mm / 次 |

1-3 |

|

14 |

Total rotaton angle |

度 |

0-90 |

|

15 |

Rolling mill working mode |

|

Manual loading and unloading |

|

16 |

Rotary feedingmechanism and working mode |

|

Worm gear |

|

17 |

Pitch circle ofrollerdriving gear |

mm |

φ180/φ186 |

|

18 |

Roll pass form: |

|

Ring hole type |

|

19 |

Roll diameter |

mm |

φ195×φ115×70 |

|

20 |

Length of the working part of the hole pattern |

mm |

|

|

21 |

Rackredprocating motion speed |

次 / 分 |

50-150 |

|

22 |

Rack stroke length |

mm |

502 |

|

23 |

Main motor power |

KW |

37 |

Technical requirements for mechanical parts

|

Componet Nam |

materlal |

ProcessIngiprOceshngmethod |

|

|

|

Head box |

Q235 welding |

leak test |

|

Main frame(overall |

|

|

|

|

Roll,core rod |

H13 H13 |

|

|

|

Track (overall) |

QT450 QT450 |

casting |

|

|

Rack slide |

Speclal wear-resistant nylon |

|

|

|

Framelcrank pin shaft |

42CrMo 42CrMo |

Tempering treatment |

|

|

Crank gear |

20CrMnTi forging |

Carburizatign,quenching and grinding of teeth |

|

|

Driving gear |

20CrMnTi forging |

Carburizatign,quenching |

|

|

Crank shaft |

42CrMo forging |

Tempering |

|

|

Drivng shatt |

42CrMo forgng |

Tempering |

|

|

connecting rod |

45# 45# |

Tempering |

|

PACKING AND DELIVERY

The products are exported to Russia, South Korea, India, Vietnam, Pakistan, Turkey, Iran, Uzbekistan, Algeria and other countries, and have been highly praised by customers.

FACTORY APPEARANCE

The company is headquartered in the Economic Development Zone of the historic city of Liaocheng, with annual sales revenue of 100 million yuan and a total area of 18 acres. It is a professional machinery manufacturing enterprise integrating automation equipment, design, manufacturing and assembly.

CUSTOMER VISIT

The company has always adhered to the principle of mutual benefit and win-win to carry out trade cooperation with domestic and foreign customers, and has established long-term and stable friendly cooperative relations with many foreign companies.

VIDEO CENTER

The products are exported to Russia, South Korea, India, Vietnam, Pakistan, Turkey, Iran, Uzbekistan, Algeria and other countries, and have been highly praised by customers.

RELATED PRODUCTS

GET A FREE QUOTE